Products

- Home

- Products

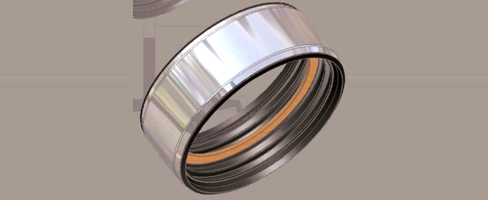

Jacking Pipe Couplings

1. Advantages of current design

The current design of the coupling includes a Stainless Steel mantle with integral rubber sealing permanently bonded to it ensuring leak proof service and further protecting the mantle from the extreme corrosive effects of some of the effluents.

-

The steel is of high specification to ensure long life and fatigue free service. The corrosion resistance of the special grade stainless Steel mantle is further enhanced by the elastomeric sealing element which prevents the steel from coming into contact with the effluent the pipeline is carrying altogether. For ceramic pipe a wood board is also incorporated in the center of the coupling to prevent the edges of the pipe butting together and damaging the ends

- Further, this product renders itself to factory fitting which prevent the errors of on site application and saves on assembly time at the site.

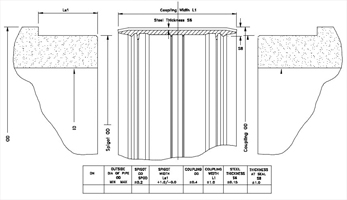

2. Technical details

-

The Steel Mantle: Depending mainly on the environment in the area of installation and to a lesser extend on the fluid to be carried in the pipeline the stainless steel mantles are specified. Currently we are using mainly AISI 316ti steel. But AISI 316L or AISI 304 can be specified. The steel in strip form of specified width are cut to accurate lengths, rolled, welded in a semi automatic rig and formed at both edges to give additional stability to the product.

- The Elastomeric Sealing Element: The profile of the rubber lining clearly shows two types of basic sealing.

(i) Compression Lip Area:Compression is the Basic sealing with the rubber element compressed between the steel mantle and spigot. This area supports the spigot and prevents excessive lateral movement. This also eliminate leaks caused by imperfections on the spigot. The compression deteriorates over time. The aim is to retain more than enough compression stress even after a 100 years of service. An initial compression of approx. 30% is shown to be the optimum as to retain enough compression even after prolonged time. Excessive values will lead to prohibitive “push-in” forces and may even cause damage the rubber element leading to failures. The residual stress can be estimated with the help of Stress Relaxation Tests which would indicate what the loss of stress would be after a week, a month, a year and 10, 50 or 100 years by extrapolation.

(ii) The “Lip” Seal Area:The addition of one or more lips to the profile gives extra flexibility. The lip sealing is less dependent on stress, and improves sealing with increasing pressure. Lips also gives added security where lateral movements do occur. Lips, if designed correctly do not increase “push in force” dramatically.

The specification for rubber is purely based on the fluid carried by the pipeline. Though predominantly EPDM other materials can be used as NBR or Fluoro-elastomers. The elastomeric profile material will be according to relevant EN specification (EN681, EN682,.)

3. Pressure Testing

Though current requirements are only for PN1 pressure grade these couplings at design stage was tested for PN6 and PN10 requirements and successfully passed these requirements. In in house pressure testing they have withstood over 40 bar

4. Production

The Steel Steel flat strips are cut to accurate length as we have very tight tolerances. These are then rolled and welded using a semiautomatic welding machine, for uniformity and quality. The welded rings are next formed to match the specification drawing and measured. The extruded rubber profile is then adhered to the steel mantle, the weld cleaned and the finished to give the final product.

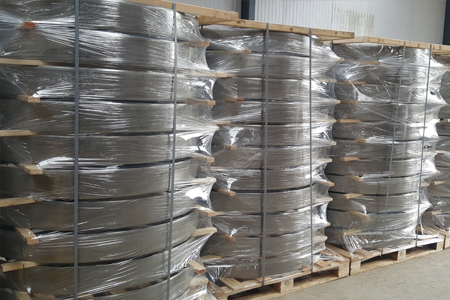

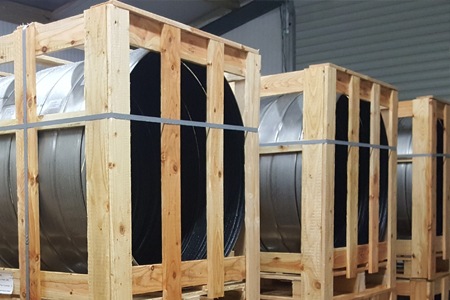

5. Packaging

Depending on the size and quantity, various packaging formats are employed. We are also able to custom make wooden cages to maximize loading and minimize transport costs. Where acceptable to the customer it is possible for products to be stacked one inside the other (size permitting) so that smaller products are transported free.

6. Lead times

Due to the efficiency and flexibility of operation we are able to respond with quick delivery times. If we receive the order at the beginning of the week in most cases we can deliver products at the end of following week to any part of Europe depending on the size of order and delivery location

7. Logistics

We have an array of carriers at our disposal to choose from. Depending on the demands of delivery we can choose part shipment, truck delivery or a container delivery. Of course the costs vary but we can select an optimum for the order.

8. Costs

We offer very competitive rates with rates varying only with reference to the Steel AAF fluctuating on a monthly basis.